All about Powder Coat Santa Clarita

Wiki Article

The Definitive Guide for Santa Clarita Powder Coating Shop

Table of ContentsSome Ideas on Powder Coating In Santa Clarita You Need To KnowSanta Clarita Powder Coating Shop Things To Know Before You BuyAbout Santa Clarita Powder Coating ShopThe smart Trick of Powder Coating In Santa Clarita That Nobody is DiscussingSanta Clarita Powder Coating Shop Things To Know Before You Get ThisThe smart Trick of Powder Coating Santa Clarita That Nobody is Discussing

Instead, the thermoplastic product just needs the moment and also temperature level essential to thaw, spurt, and produce the film-like finishing. Unlike with thermoset material, which undertakes a chain reaction during the treating phase, thermoplastic materials do not change their physical or chemical properties when warmth is applied. They can be remelted, changed, and also recycled for future covering applications.

Normally, thermoset powders are just used using the ESD approach (powder coating in santa clarita). This restriction exists because dipping preheated parts into thermoset powder can cause any kind of excess powder to cross-link due to built-up as well as recurring warmth within the fluid bed. As the cross-linking reaction creates long-term modifications to the powder material, such occurrences would lead to extreme layer material waste.

Since steels can be electrically based, the layer product is usually used to steel substrates via the electrostatic spray deposition technique, yet they can additionally be used by means of the fluidized bed technique. On the various other hand, because non-metals can not be adequately grounded, they need that the powder layers be used through the fluidized bed powder layer method.

Rumored Buzz on Powder Coat Santa Clarita

The procedure also enables for overspray product to be collected as well as recycled as opposed to lost, which reduces the quantity of waste product calling for disposal, raises the finish product utilization rate, and lowers the cost of products gradually. Limitations of Powder Layer Although the powder coating process offers several important advantages over fluid layer, there are also constraints to the procedure.As discussed formerly, substrate materials have to be able to withstand the temperature demands of the curing phase to be suitable for powder layer applications. Even if a material can endure the warmth, attaining an even finish can still show to be bothersome, particularly for thin or multi-color finishings. Thin finishings are tough to produce as it is challenging to manage the amount of powder product that is put on the substrate throughout the application phase while still making sure an also finish.

While the powder covering procedure can have reduced costs with time, for specific layer applications, it might be much more cost-effective to make use of liquid coatings. For example, while powder layered components generally have faster turnaround, huge, thick, or hefty components tend to require greater temperature levels and also even more extensive healing and drying times; not only would these extended treatment schedules postpone the production process, they would also lead to greater energy expenses.

Santa Clarita Powder Coating for Beginners

These service providers can develop and also build personalized systems for layer certain parts, which makes sure that the parts are coated regularly as well as to the required specs. Although pricey as measured by the initial investment, throughout numerous years the latter option can demonstrate a lot lower cost-per-part. Some manufacturers might select to complete finishing operations internal, in which instance they would need to purchase acquiring or blog here purchasing powder covering devices.

View Powder Coating Plus, Inc. Santa Clarita in a full screen map

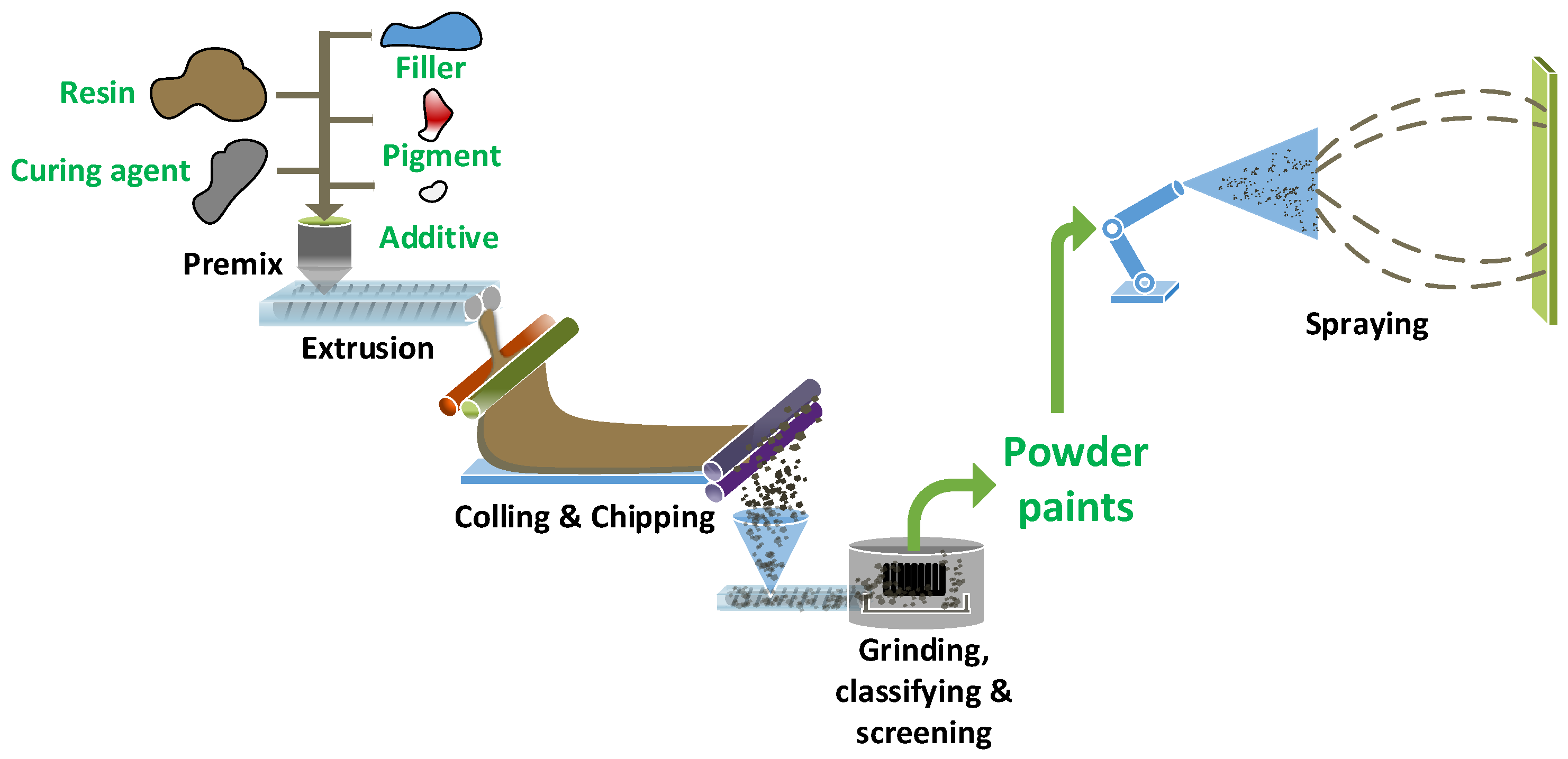

Powder finish is a dry completing process made use of to use a dry finish product. The finish product is made up of carefully ground bits of resin and also pigment for shade, along with other ingredients for certain functions such as gloss or hardness.

Because its introduction even more than 40 years back, powder finish has expanded in popularity and is currently made use of by lots of manufacturers of usual family and also commercial products. In The United States and Canada, it is approximated that even more than 5,000 finishers apply powder to produce high-grade, long lasting coatings on a vast selection of products.

i loved this

Some Known Factual Statements About Santa Clarita Powder Coating

Theoretically, 100 percent of the powder overspray can be recuperated and reused. santa clarita powder coating. Even with some loss in the collection filtering systems and also on component hangers, powder utilization can be very high. Oversprayed powder can be recovered by a healing system as well as went back to a feed receptacle for recirculation via the system.The cured finish has a various chemical structure than the fundamental resin. Thermosetting coverings are heat-stable and also, unlike polycarbonate powders, will not soften back to the fluid stage when reheated. Thermoset powders can likewise be used by spray application to establish thinner films with far better look than some thermoplastic powder coverings.

The procedure was presented in the USA in the 1960s, as well as fast development proceeded for the next 30 years. Pretreatment for Powder The go to these guys initial step in the powder coating procedure is to prepare or pretreat the components. The product to be covered is revealed to cleansing and also pretreatment operations to ensure that surface areas to be covered are clean as well as without oil, dust, oils, corrosion as well as other impurities.

Powder Coating In Santa Clarita for Dummies

The particular pretreatment process selected relies on the characteristics of the layer and also substrate materials, as well as on the end use the item being covered. Pretreatments most usually made use of in powder coating are iron phosphate for steel, zinc phosphate for galvanized or steel substratums, as well as chromium phosphates or non-chrome treatments for light weight aluminum substratums.Dry-in-place pretreatment items, such as a seal rinse over an alkali metal phosphate, can reduce the variety of stages called for before powder coating application. Chrome dried-in-place therapies work on multi-metal substrates as well as may be the single pretreatment needed for some applications. Non-chrome innovations are generally used as well. Non-chrome aluminum therapies have actually come to be preferred over time with superb performance residential or commercial properties.

They are after that ready to be covered. For many useful applications, a mechanical pretreatment such as sand or shot blasting can be used. With this method, high-velocity air is made use of to drive sand, grit or steel shot toward the substratum, developing a support pattern on the part that boosts the bond of the powder layer to the substratum.

The Buzz on Powder Coat Santa Clarita

Mechanical blasting can be used alone or along with a chemical therapy. The blast operation creates an outstanding surface area for bond yet does not add any additional corrosion security. santa clarita powder coating shop. In most cases, the blasted surface is very first coated with a suitable guide to include added deterioration defense for blast-only surfaces.Report this wiki page